Stirling Engines

and Construction Tricks

Links to Hot Air and Stirling Engines

THE HISTORY

The Stirling engine

was invented by Rev. Robert Stirling in 1816.

He was a Scottish

minister. At that time, Stirling engines

were recognized as

a safe engine that could not explode

like steam engines

of that era often did.

Nei motori a ciclo

Stirling il fluido motore (gas) non ha

contatti o scambi

con l'esterno, ma è ermeticamente

confinato all'interno

del motore, quindi non vi sono emissioni

inquinanti. Il ciclo

di funzionamento è molto simile al ciclo

di Carnot, quindi

in questi motori il rendimento approssima

il massimo ottenibile

da un motore termico che funzioni

fra le stesse due

temperature estreme. I motori Stirling

possono funzionare

fra temperature molto vicine:

anche solamente con

7°C di differenza. Sono diventati

interessanti in questi

ultimi anni come possibili motori

puliti ed ecologici

per la conversione diretta dell'energia

raggiante solare.

Il ciclo Stirling inverso ha applicazioni

nei liquefattori di

gas come l'aria e l'azoto.

My friend Adolf Cortel

from Spain shows two models

of Stirling motors

to VIP's at POS2 (Physics on Stage 2002)

in Noordwijk (The

Netherlands).

The motor on the left

is of the kind illustrated

in the following sketch.

THE

STIRLING MOTOR WORKING PRINCIPLE:

The cycle of a generic

Stirling engine is as follows:

Air at the bottom

of the cylinder (E) is heated,

thus expanding and

forcing the piston (A) upward.

At this time the displacer

(B) is driven downward

to the bottom of the

cylinder. Since the displacer

is of a smaller diameter

than the cylinder, the

hot air rushes around

the displacer to the cool

end of the engine

(F). Once in the top end of

the cylinder, the

hot air begins to contract,

sucking the piston

downward. Now the displacer

moves upward, forcing

all the cool air from

the top end of the

cylinder into the bottom end.

Here the air is heated

and the cycle begins again.

Note the 90° phase

shift between the displacer

and the active piston.

Furthermore, this motor runs

completely silent!

SEE

HERE AN ANIMATED STIRLING ENGINE

Thanks to M. Abendschoen

and its web site:

http://michael.abendschoen.bei.t-online.de/hauptmenue.html

YOU

MUST SEE ALSO IMEDIATLY:

http://www.newenergyshop.com

This is the beautiful

Stirling engine from EXERGIA GERMANY

(WWW.EXERGIA.DE)

which incredibly runs on unconcentrated

solar radiation on

its top surface. The same firm sells

also other interesting

engines both in kit and fully assembled.

AN

EXTRAORDINARY STIRLING MOTOR

WITH

THE "RINGBOM" TECHNOLOGY: SEE.

THE TEST TUBE STIRLING MOTOR

This test tube Stirling

engine is likely the simplest to construct.

It makes an ideal

gift for that budding scientist or engine

enthusiast. Ideal

as science project and teaching aid.

A

BEAUTIFUL SELF EXPLAINING

ANIMATION

Note the 90° phase

shift between the displacer

and the active piston.

Heath is on the left cilynder.

By courtesy of: Steffen

Tschirch, CAD Zeichen Büro

Hildesheimer-Str.

401, 30880 Laatzen

Fax.: 49 5102

914732

http://www.cad-zeichen-buero.com

E-Mail: info@cad-zeichen-buero.com

ANOTHER

INTERESTING

CONFIGURATION

symilar to that of

the above animation:

Owing to the simplified

mechanism of the 90° shifted

displacements of the

pistons, this structure could be

easier to make.

CONSTRUCTION TRICKS AND HINTS

1.

In small engines the connecting rod small end from

the piston or displacer

to the crankshaft may be done by means

of an intermediary

small piece of flexible rubber tubing.

2.

In small engines the piston may be in the form of a thin flexible

rubber membrane, like

in those barely visible in the above photography

of Adolf Cortel from

Spain and in the following image:

as is used in

the following fine "cofee cup" engine

(sold

also in kit form):

3.

Long life, self lubricating and very low friction pistons are made of

grafite, with the

cylinder made of glass tube. Suitable cylinders

are made by a glass

syringe.

4.

As in the above "cofee cup" model Stirling motor, the bushes and the axle

bearings are suitably

made by teflon. Remember to keep frictions as small

as possible.

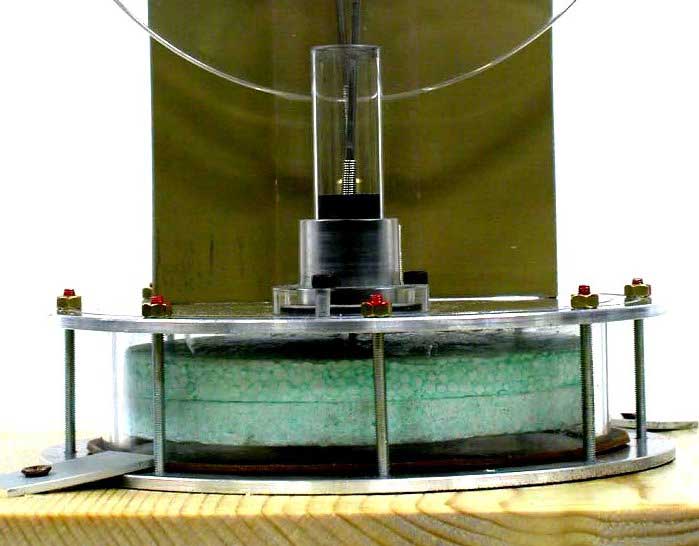

This is a detail of

a Stirling motor constructed in the Laboratory

of

the Museum of Physics of Cagliari University.

Cylinder: glass; piston:

graphite; displacer: styrofoam. Under

a working temperature

difference of 20 °C it turns at 150 rpm.

Note the couplig between

the piston and the connecting

rod made by a spring

of inox harmonic wire.

STIRLING

ENGINE SCHMIDT THEORY

See

the site of Koichi Hirata

See

also the Alan Altman site

for

a calculation program.